Industry News

Fuel system

Views : 819

Update time : 2023-12-28 17:48:23

3. Fuel system

Before starting a new engine, the fuel tank should be filled with fuel. Before refueling, check whether the fuel tank and fuel pipelines are clean; burn

The oil filter should be installed on the engine after being filled with clean fuel.

Most diesel fuel available in the market can be used on CUM engines, but must meet viscosity, sixteen

Requirements for performance indicators such as alkane number, flow rate, water and sediment, and oil point: viscosity should be maintained at an ambient temperature of 40 ℃

Between (1.3~5.8) x10m2/s; When the ambient temperature is above 0 ℃, the cetane number should not be lower than 40. When the ambient temperature is low At 0 ℃. The cetane number should not be lower than 45; The sulfur content shall not exceed 0.5 weight percentage; Water and sediment must not exceed If the volume percentage exceeds 0.05, the fuel should be kept clean and free of moisture or impurities, otherwise it will cause the fuel pump and injector to tighten

Heavy damage; The cloud point of the selected fuel (the temperature at which paraffin crystals first appear) must be higher than the minimum ambient temperature at which the fuel operates

Lower the temperature by 6 ℃, otherwise the wax crystals will cause fuel system blockage.

Before starting a new engine, the fuel tank should be filled with fuel. Before refueling, check whether the fuel tank and fuel pipelines are clean; burn

The oil filter should be installed on the engine after being filled with clean fuel.

Most diesel fuel available in the market can be used on CUM engines, but must meet viscosity, sixteen

Requirements for performance indicators such as alkane number, flow rate, water and sediment, and oil point: viscosity should be maintained at an ambient temperature of 40 ℃

Between (1.3~5.8) x10m2/s; When the ambient temperature is above 0 ℃, the cetane number should not be lower than 40. When the ambient temperature is low At 0 ℃. The cetane number should not be lower than 45; The sulfur content shall not exceed 0.5 weight percentage; Water and sediment must not exceed If the volume percentage exceeds 0.05, the fuel should be kept clean and free of moisture or impurities, otherwise it will cause the fuel pump and injector to tighten

Heavy damage; The cloud point of the selected fuel (the temperature at which paraffin crystals first appear) must be higher than the minimum ambient temperature at which the fuel operates

Lower the temperature by 6 ℃, otherwise the wax crystals will cause fuel system blockage.

Related News

Read More >>

From Durability to Recyclability: Redefining the Lifecycle of an Engine Piston

From Durability to Recyclability: Redefining the Lifecycle of an Engine Piston

Jul .31.2025

At the core of every internal combustion engine, from the workhorses powering our global supply chain to the vehicles we rely on daily, lies a component of immense power and precision: the piston.

Dec .26.2023

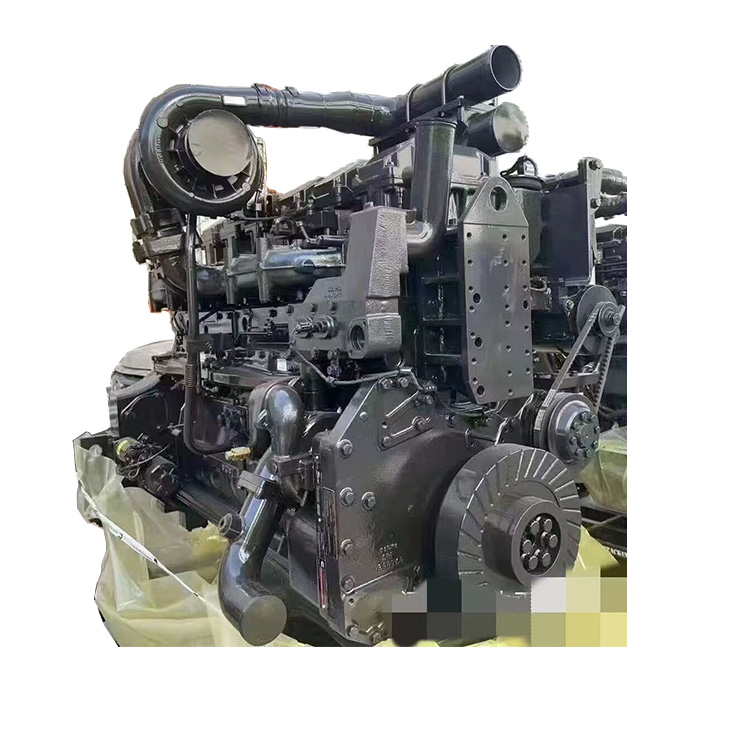

As a well-known brand engine on par with CAT and Detroit, CUM products are widely used in petroleum and petrochemical, water and hydropower

Widely used in various fields such as transportation, engineering, mining, and agriculture. How to maintain CUM

Widely used in various fields such as transportation, engineering, mining, and agriculture. How to maintain CUM